No products in the cart.

Need help? Call us:

+1 (833) 763-7837

Menu

Categories

- Accessories

- Air Purification Accessories

- Antennas

- Attenuators

- Barcode Scanners

- Batteries and Chargers

- Bottles and Dispensers

- Cables - Misc

- Carrying Straps, Lanyards and Harnesses

- Carts

- Case and Cart Accessories

- Cases

- Cathodic Protection Accessories

- Coaxial

- Crimper Accessories

- Datacom Accessories

- Dry Block Bath Inserts

- EMI Accessories

- Enclosure Accessories

- FIber Optic Accessories

- Fiber Optic Cables

- Gas Detection Accessories

- General Accessories

- GPIB Adapters

- Heating Elements

- Hipot Accessories

- Hoses - Miscellaneous

- HVAC Accessories

- Induction Heater Accessories

- Input Cards

- Jacks /Adapters /Plugs /Clips /Terminators/Coaxial

- Jobsite Storage and Cabinets

- Knockout Accessories

- Lab Accessories

- LCR Test Fixtures

- LED and LCD Displays

- Manuals

- Material Handling Accessories

- Microphones

- Microscope Accessories

- Motors

- Options

- Pinhole/Holiday Detector Accessories

- Plumbing Accessories

- Precision Measuring Instrument Accessories

- Pressure Calibrator Modules

- Printers and Printing Supplies

- Probes

- Rack Mounts and Stands

- Repair Parts and Fuses

- Scale Accessories

- Shunts

- Software

- Soldering Accessories

- Spectrum Analyzer Accessories

- Static Control Accessories

- Switch and Semiconductor Modules/Access

- Test Fixtures

- Test Leads and Instrument Accessory Kits

- Thermal Imager Accessories

- Training and Education

- Underground Utility Location Accessories

- Vibration Accessories

- Video Accessories

- Voltage Transformer

- Warranty and Calibration

- Amplifiers / Preamps / Preamplifiers

- Audio Equipment

- Automotive Test Tools

- Battery Testing

- Blower Door and Duct Testing

- Borescopes / Boroscopes

- Clamp Meters

- Cleanroom

- Color and Appearance

- Conduit Benders

- Current Sensors

- Datacom and Networking Products

- Dataloggers Data Acquisition

- Decade Boxes

- Distance Meter

- Electrical Parts and Products

- Cable and Wire

- Cable Reels

- Electrical Cord

- Electrical Jumpers and Pigtails

- Electrical Parts

- Electrical Plugs and Connectors

- Line Splitters

- Lockout / Tagout

- Outlet Boxes

- Pulling Products

- Pushbutton Pendant Stations

- Receptacle Testers

- Temporary Power Distribution

- Terminal Blocks and Strips

- Terminals and Crimps

- Wall Plates

- Wire Management

- Wire Ties

- Work Lighting and String Lighting

- Enclosures and Boxes

- Environmental Testers / Physical Property

- Anemometer / Air Flow

- Barometers and Altimeters

- Chlorine Tester

- Dissolved Oxygen Meter / Fluoride

- EMF / ELF Meter

- Heat Index Monitors

- Humidity Meters

- Hygrometers

- Moisture Meters

- Nuclear Radiation Monitors

- PH / ORP Meters

- Psychrometer

- Refractometers / BRIX

- Scales / Weight

- Sound Level Meters

- Stopwatches / Timers / Clocks

- Water Quality Accessories

- Water Quality Meters

- Weather Measurement

- Wind Tunnels

- Flow Measurement

- Force / Torque / Hardness Meters

- Gas Detection

- Ground Testers

- Health and Safety

- HVAC Equipment and Instruments

- Automotive RRR Machines

- Brazing

- Combustion Analyzers

- Hose Adapters, Valves and Parts

- HVAC - Testing - Adjusting - Balancing

- HVAC Equipment - Misc

- HVAC Manifolds and Gauges

- HVAC Vacuum Pumps

- Refrigerant Leak Detectors

- Refrigerant Recovery Machines

- Refrigerant Recovery Tanks

- Smoke Pump Test Kits

- Tubing Tools

- Vacuum Gauges

- Hydraulic Cylinders

- Indoor Air Quality

- LCR Meters / Impedance Measurement Products

- Leakage Detectors

- Life Sciences Equipment

- Autoclaves and Sterilization

- Bunsen Burners

- Centrifuges

- Cold Storage

- Colony Counters

- Dry Block Heaters and Cooling Blocks

- Environmental Test Chambers

- Flame Photometers

- Flocculators

- Fluidized Bed Baths

- Gel Imaging Electrophoresis

- Glassware Washers-Dryers

- Heating Mantles / Electromantles

- Homogenizers

- Incubators

- Kjeldahl Apparatus

- Lab Apparatus - Misc

- Laboratory Ovens

- Laboratory Pumps

- Laboratory Water Purification Systems

- Magnetic Bead Based Purification

- Melting Point Apparatus

- Mixers Rotators and Stirrers

- Pipettes

- Reaction Station

- Recirculating Chillers / Coolers

- Refrigerated Heating Circulators

- Rotary Evaporators

- Shakers and Rockers

- Slide Warmers

- Spectrophotometer

- Thermal Cycler / PCR

- Titrators

- Water Baths and Liquid Baths

- Logic Analyzers

- Materials Testing

- Megohmmeter / Insulation Resistance Testers

- Micro-Ohmmeter / Milliohmmeter

- Microscopes

- Multimeters

- Network Analyzer

- Oscilloscopes

- Panel Meters

- Personal Protective Equipment

- Phase / Motor / Transformer Testing

- Power Measurement

- Power Supplies

- Process / Calibration

- Programmers / IC and RAM Testers

- Protocol Analyzers

- Prototyping

- Radiometric

- Reliability / Preventative Maint / Rotational

- RF, Microwave, EMI

- Safety Testing / Surge Testing

- Signal Generators / Counters

- Signal Level Meters - CATV / CCTV / Satellite

- Solar Analyzers

- Soldering Equipment

- BGA Rework Station

- Chemicals

- Cleaning Pins and Drills

- Depaneling Systems

- Desoldering Equipment/Rework Stations

- Desoldering Irons

- Dispensing Equipment

- Flux

- Flux Remover

- Fume Extraction

- Hot Air Guns

- Hot Air Pencils

- Lead Forming Equipment

- Nitrogen Generation

- Nozzles

- PCB Supports and Holders

- Pre-Heater

- Solder

- Solder Wick

- Soldering Equipment

- Soldering Irons

- Soldering Pots

- Soldering Robots

- Soldering Stands

- Soldering Stations

- Soldering Tip Cleaners

- Soldering Tip Thermometers

- Soldering Tweezers

- Sponges and Brass Wool

- Thermal Wire Strippers

- Tips

- Vacuum Pick-Up Tools

- Sporting / Hunting / Law Enforcement Optics

- Static Control

- Surveying / Construction Measurement

- Thermal Imagers

- Thermometers

- Thickness Gauges

- Tools

- Blackeners

- Cable Cutters

- Cable Strippers

- Cable Tie Guns

- Combination Squares

- Conduit Tools

- Crimpers

- Cutters

- Cutting Tools

- Datacom / Fiber Optic Tools

- Drill Bits and Sets

- Drill Rod

- Dry Lubricants

- Electric Screwdrivers

- Feeler Gage

- Fiber Optic Cable Tools and Fiber Scopes

- Flashlights and Headlights

- Ground Flat Stock

- Hex Drivers, Torx Drivers

- Hose Benders

- Hose Clamps

- Hot Melt

- HVAC Service Tools

- Insulated Tools

- Keystock

- Knockout Tools

- Layout Fluid

- Level Measurement

- Maintenance Kits

- Multi-Tools

- Other Hand Tools

- Pliers

- Pneumatic Hand Tool Operators

- Power Tools

- Probes & Scribes

- Punch & Die Sets

- Punchdown Tools

- Remote Hydraulic Pumps

- Screwdrivers

- Shims & Shim Stock

- Sockets & Ratchets

- Spatulas

- Telecom Service Tools

- Telescopic Tools

- Threaded Rod

- Tool Kits

- Tool Wrap

- Tweezers

- Vises

- Wire

- Wire Strippers

- Wrenches & Wrench Sets

- Toys / Cool Stuff

- Transmission Line/Station Testing

- Cable Testing

- Circuit Breaker Testers

- Corona Detection

- Dielectric Oil Testing

- High Current Detectors / Indicators

- High Voltage Detectors / Indicators

- Hot Sticks

- Phasing Sticks

- Primary Injection Test Equipment

- Safety Equipment

- Secondary Injection Test Equipment

- SF6 Gas Leak Detectors

- Transformer Testing/TTR

- Transmission Cable Height Meters

- Video Distribution Equipment

- Video Test Equipment

- Voltage / Continuity and Non-Contact Testers

- Wire Tracers / Circuit Breaker Tracers

- Workbenches

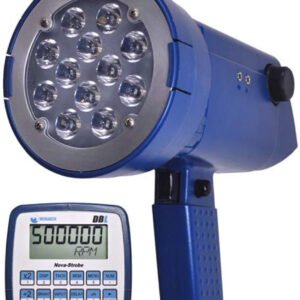

Fluke 820-2 LED Stroboscope

Brand:

34 people are viewing this product right now

$2,116.38

Shipping calculated at checkout.

Estimated delivery:3 days

Fluke 820-2 High Intensity LED Stroboscope

- 820-2 LED Stroboscope

- High-intensity 7-LED array – 4,800 Lux @ 6,000 FPM/30cm

- High efficiency LED solid-state light source with uniform flash characteristics allows for higher flash rates – 30-300,000 FPM (flashes per minute)

- Digital pulse width modulation for exceptionally sharp images at high speeds

- Rugged, durable design utilizes solid-state LEDs with no filaments, gases, hollow cavities, or glass – (1 meter drop)

- Quartz-accuracy control system provides high accuracy – 0.02% (+/- 1 digit)

- Multi-line LCD display

- Check the rotating speed of machinery without physical contact or need for reflective tape

- Advance or retard flash timing for viewing gear teeth, cutting surfaces, repeats, or drifting equipment

- Simple push button operation with 2x and ÷2 buttons for easy adjustment

SKU:

Fluke 820-2

EAN:

095969767705

Tags: Reliability / Preventative Maint / Rotational, Stroboscopes

Categories: Stroboscopes

Have any Questions?

Feel free to Get in touch

Guarantee Safe and Secure Payment Checkout

Description

Fluke 820-2 – LED Stroboscope

- High efficiency LED solid-state light source with uniform flash characteristics allows for higher flash rates – 30-300,000 FPM (flashes per minute)

- Digital pulse width modulation for exceptionally sharp images at high speeds

- Rugged, durable design utilizes solid-state LEDs with no filaments, gases, hollow cavities, or glass (1 meter drop)

The Fluke 820-2 LED Stroboscope is more than just a tool to measure rotational speed of machinery without physical contact. It is also an excellent diagnostic tool for a wide variety of applications in a vast range of industries. Even better, it’s a Fluke tool which means that it is rugged and ergonomic. It allows clear observation of machinery in motion – all cyclic motion can be slowed or stopped visually in order to note performance, observe dynamic motion, measure speed, or photograph/video the action.

The Fluke 820-2 is far superior to its competitors on every front including feature set, form factor and brand promise. The stroboscope can be used as a strobe tachometer to measure the speed instead of using a laser tachometer. In order to use the stroboscope, you will need access to visibly see the object to measure and it needs to have some marking on it to use as a reference point. A strobe tachometer is a good tool to have because you can’t always get access to the machine shaft to stick a piece of reflective tape to use a laser tachometer or make contact with the moving shaft to use a contact tachometer.

Rugged, compact and easy-to-use

Investigate and observe potential mechanism failure with confidence on a variety of machinery, in a wide range of industries, without making physical contact with the machine. The Fluke 820-2 LED Stroboscope is a rugged, compact, portable strobe ideal for stop motion diagnostics, mechanical troubleshooting, and process or product research and development.

The Fluke 820-2 LED Stroboscope is a simple, easy to use tool to stop motion for measurement and diagnostic purposes allowing you to:

Identify the running speed of rotating equipment without stopping the operation or making contact with machinery

Stop motion for diagnoses of parasitic oscillations, flaws, slippage or unwanted distortions

Measure speed of rotation or frequency of a rotating shaft, speaker, or mechanical part

Identify part numbers or other markings

Adjustable flash duration

For most applications the standard flash duration will work well without adjustment. In other applications with higher rpm or larger rotating objects with high surface speeds, an adjustable flash duration is needed. In high speed applications, objects may move during the brief period of a single flash, resulting in a blurred image. By decreasing flash duration, objects have less time to move and the image will appear sharper.

Common applications for the 820-2

The Fluke 820-2 LED Stroboscope is more than just a tool to measure rotational speed of machinery without physical contact. It is also an excellent diagnostic tool for a wide variety of applications:

- Belt driven machines-HVAC fans, pumps

- Roller bearings, shafts, gear teeth or other machine components

- Clutches and cogwheels

- Foundations-resonance vibrations

- Cable or piping wear or damage

- Mixing and dosage processes

In addition, the stroboscope can be used as a strobe tachometer to measure speed instead of using a laser tachometer. In order to use the stroboscope, the component under measure must be visible, and have an identifying mark that can be used as a point of reference. A strobe tachometer is a useful tool because you can’t always get access to the machine shaft to stick a piece of reflective tape to use a laser tachometer or make contact with the moving shaft to use a contact tachometer-using a stroboscope you can “stop” the shaft down to 30 RPM (FPM).

Use the 820-2 for:

- Turbines that vary in speed and change speed frequently

- Variable Frequency Drive motors that vary in speed, but do not change frequently

- Find belt rotation speed and look for belt slippage

- Find machine element components – fan blades, pump vanes, compressor screws, and gear teeth

- RPM measurement and frequency investigation

- Slip measurement

Use the Fluke 820-2 LED Stroboscope in a variety of industries:

Electronics/electrical engineering

- Observe the anchor swing from synchronic and asynchronous motors, carbon brush of the collectors and sliding rings. Find mistakes on speakers, record players, magnetic tape recorder, relay, contact rectifiers, power switch, phone selector, home appliances, kitchen equipment, ventilators, turbines, vibrators, counters, speakerphones, sorting-machines, centrifuges, electrical tools and equipment.

- Find errors caused by work process on manufacturing machines-wrappers, cabling machines, isolated machines, wireless printing machines, cutting machines and drill machines.

- Control the synchronization of motors and machines as well as their leakage and tarnish behavior. Check the behavior of motors, machines, and drives for power drain. Identify material stress as well as fatigue by wave motion reverberations at higher machine efficiency.

Machine construction

- Investigate meshing of gears, control of drives, ball bearings, couplings, lever movement, linkages, cylinders, valve clip tongue and valve clip leverage, resonance vibrations, and early detection of fatigue of the material from high load.

- Control the work process on high-speed machines. Check the compliance of rotational parts of motors, machine and manufacturing equipment, and the behavior of couplings, belts and chain-drives at high speeds.

- Observe the work processes of centrifuges, pressure/cut machines, automatic punching, riveting machines, screwing machines, grinding machines, polishing machines and boring machines. Observe the automatic moving processes and play of machines and mechanical equipment that is out-side what can be seen by the human eye.

Chemical manufacturing

- Control the mixing and dosing processes. Observe mixers, pumps, regulation systems, transport bands, package machines, dosing and sorting machines, tablet machines, bottle filling machines, closure machines, etc.

- Observe the product in dry centrifuges and air pressure machines, conveying systems, swing filters and crushing plants, etc.

Automotive and motor manufacturing

- Adjust the ignition and the valves. Check the valve lever movement, valve spring vibration, and injection operations in combustion engines. Control of the various work processes in manufacturing of automatic and machines all of kinds.

- Observe the vibration of motors, hangers, transmission shafts, springs, wind generators, and light machines.

Optics manufacturing

- Test camera closures. Control transport of film cameras and projectors. Observe the drive elements, cooling fan, and the return flow of movie projectors. Investigate the work process on lens-grinding machines.

- Perform movement studies seen in the fast movement of objects through film recordings.

Print, paper, and cardboard manufacturing

- Observe the passer marks and control the printing process. Watch multicolor printers in order to assess the print quality relative to the rate.

- Check on package machines, folding box automation, cutting automation and adhesive automation. Control the work process of the punching, printing, and sorting automation. Control the rotary knives, waltz, transport rollers, gears, stores, waves, etc.

Mining

- Observe shiver and swinging filters, transport bands, and centrifuges. Control the generators, drive machines, rock drills and other mechanical equipment.

Shipbuilding, aircraft construction

- Determine the appearance of cavitation bubbles on propellers at experimental models. Control the movement in marine engines, generators, E-machines, and air systems.

- Observe the behavior of propellers and air screws at different rpm (drew behavior and fluid behavior).

Medical

- Observe the drilling process in medical institutions.

- Set the responsive assets on light pulses of different frequencies (e.g. an epileptic)

- Use in laboratories, research institutions, schools, universities, and technical training facilities

- Observe the work processes for demonstration and experimental purposes. Use as visual evidence for theoretical opinions where visualization of optics are not detectable.

| Item | Description |

| 1 | Display |

| 2 | Power Button– Push  to turn on the Product. to turn on the Product.Push and hold  for 2 seconds to turn off the for 2 seconds to turn off theProduct. |

| 3 | Push  to divide the current set value by two. to divide the current set value by two.The scroll speed increases when  is iscontinuously held down. |

| 4 | External trigger connection |

| 5 | Setup– Push  to move between different to move between differentsettings and modes. |

| 6 | Push  to double the current set value. Speed of to double the current set value. Speed ofthe scroll increases when this button is held down. |

| 7 | LED strobe |

| 8 | Push the trigger ( ) up to increase the current set ) up to increase the current setvalue. Push  down to decrease the current set down to decrease the current setvalue. Speed increases when  is held down. is held down. |

| 9 | Battery compartment |

Reliability / Preventative Maint / Rotational/Stroboscopes Template | |

|---|---|

| Style (Stroboscope) | Hand Held |

| External Trigger | Yes |

Product General Attributes | |

| Product Weight | 0.24 KILOS (0.529 LBS) |

| Product Height | 2.25 IN |

| Product Length | 7.5 IN |

| Product Width | 2.4 IN |

| Country of Origin | Germany |

| Shipping Height | 3.25 IN |

| Shipping Length | 10.25 IN |

| Shipping Width | 8.75 IN |

Be the first to review “Fluke 820-2 LED Stroboscope”

You must be logged in to post a review.

Manuals/Guides

| Weight | 0.24 lbs |

|---|---|

| Dimensions | 7.5 × 2.4 × 2.25 in |

Related products

Sale

SPM Vibration 18432 – Stroboscope (100 to 12500fpm)

Sale

Shimpo DT-3011N-EU – Heavy duty, Xenon Stroboscope (Euro Plug – 240 VAC)

Sale

Shimpo DT-3015N – Heavy Duty, Rechargeable Battery Powered Stroboscope

Our team of knowledgeable professionals is here to help you make informed decisions. Whether you need product recommendations, technical support, or guidance on your purchase, we're just a click away.

Contact Us Now:

📧 sales@nestesinstruments.com

📞 +1 (833) 763-7837

Let us assist you in finding the perfect solution!

Contact Us Now:

📧 sales@nestesinstruments.com

📞 +1 (833) 763-7837

Let us assist you in finding the perfect solution!

Reviews

There are no reviews yet.