No products in the cart.

Need help? Call us:

+1 (833) 763-7837

Menu

Categories

- Accessories

- Air Purification Accessories

- Antennas

- Attenuators

- Barcode Scanners

- Batteries and Chargers

- Bottles and Dispensers

- Cables - Misc

- Carrying Straps, Lanyards and Harnesses

- Carts

- Case and Cart Accessories

- Cases

- Cathodic Protection Accessories

- Coaxial

- Crimper Accessories

- Datacom Accessories

- Dry Block Bath Inserts

- EMI Accessories

- Enclosure Accessories

- FIber Optic Accessories

- Fiber Optic Cables

- Gas Detection Accessories

- General Accessories

- GPIB Adapters

- Heating Elements

- Hipot Accessories

- Hoses - Miscellaneous

- HVAC Accessories

- Induction Heater Accessories

- Input Cards

- Jacks /Adapters /Plugs /Clips /Terminators/Coaxial

- Jobsite Storage and Cabinets

- Knockout Accessories

- Lab Accessories

- LCR Test Fixtures

- LED and LCD Displays

- Manuals

- Material Handling Accessories

- Microphones

- Microscope Accessories

- Motors

- Options

- Pinhole/Holiday Detector Accessories

- Plumbing Accessories

- Precision Measuring Instrument Accessories

- Pressure Calibrator Modules

- Printers and Printing Supplies

- Probes

- Rack Mounts and Stands

- Repair Parts and Fuses

- Scale Accessories

- Shunts

- Software

- Soldering Accessories

- Spectrum Analyzer Accessories

- Static Control Accessories

- Switch and Semiconductor Modules/Access

- Test Fixtures

- Test Leads and Instrument Accessory Kits

- Thermal Imager Accessories

- Training and Education

- Underground Utility Location Accessories

- Vibration Accessories

- Video Accessories

- Voltage Transformer

- Warranty and Calibration

- Amplifiers / Preamps / Preamplifiers

- Audio Equipment

- Automotive Test Tools

- Battery Testing

- Blower Door and Duct Testing

- Borescopes / Boroscopes

- Clamp Meters

- Cleanroom

- Color and Appearance

- Conduit Benders

- Current Sensors

- Datacom and Networking Products

- Dataloggers Data Acquisition

- Decade Boxes

- Distance Meter

- Electrical Parts and Products

- Cable and Wire

- Cable Reels

- Electrical Cord

- Electrical Jumpers and Pigtails

- Electrical Parts

- Electrical Plugs and Connectors

- Line Splitters

- Lockout / Tagout

- Outlet Boxes

- Pulling Products

- Pushbutton Pendant Stations

- Receptacle Testers

- Temporary Power Distribution

- Terminal Blocks and Strips

- Terminals and Crimps

- Wall Plates

- Wire Management

- Wire Ties

- Work Lighting and String Lighting

- Enclosures and Boxes

- Environmental Testers / Physical Property

- Anemometer / Air Flow

- Barometers and Altimeters

- Chlorine Tester

- Dissolved Oxygen Meter / Fluoride

- EMF / ELF Meter

- Heat Index Monitors

- Humidity Meters

- Hygrometers

- Moisture Meters

- Nuclear Radiation Monitors

- PH / ORP Meters

- Psychrometer

- Refractometers / BRIX

- Scales / Weight

- Sound Level Meters

- Stopwatches / Timers / Clocks

- Water Quality Accessories

- Water Quality Meters

- Weather Measurement

- Wind Tunnels

- Flow Measurement

- Force / Torque / Hardness Meters

- Gas Detection

- Ground Testers

- Health and Safety

- HVAC Equipment and Instruments

- Automotive RRR Machines

- Brazing

- Combustion Analyzers

- Hose Adapters, Valves and Parts

- HVAC - Testing - Adjusting - Balancing

- HVAC Equipment - Misc

- HVAC Manifolds and Gauges

- HVAC Vacuum Pumps

- Refrigerant Leak Detectors

- Refrigerant Recovery Machines

- Refrigerant Recovery Tanks

- Smoke Pump Test Kits

- Tubing Tools

- Vacuum Gauges

- Hydraulic Cylinders

- Indoor Air Quality

- LCR Meters / Impedance Measurement Products

- Leakage Detectors

- Life Sciences Equipment

- Autoclaves and Sterilization

- Bunsen Burners

- Centrifuges

- Cold Storage

- Colony Counters

- Dry Block Heaters and Cooling Blocks

- Environmental Test Chambers

- Flame Photometers

- Flocculators

- Fluidized Bed Baths

- Gel Imaging Electrophoresis

- Glassware Washers-Dryers

- Heating Mantles / Electromantles

- Homogenizers

- Incubators

- Kjeldahl Apparatus

- Lab Apparatus - Misc

- Laboratory Ovens

- Laboratory Pumps

- Laboratory Water Purification Systems

- Magnetic Bead Based Purification

- Melting Point Apparatus

- Mixers Rotators and Stirrers

- Pipettes

- Reaction Station

- Recirculating Chillers / Coolers

- Refrigerated Heating Circulators

- Rotary Evaporators

- Shakers and Rockers

- Slide Warmers

- Spectrophotometer

- Thermal Cycler / PCR

- Titrators

- Water Baths and Liquid Baths

- Logic Analyzers

- Materials Testing

- Megohmmeter / Insulation Resistance Testers

- Micro-Ohmmeter / Milliohmmeter

- Microscopes

- Multimeters

- Network Analyzer

- Oscilloscopes

- Panel Meters

- Personal Protective Equipment

- Phase / Motor / Transformer Testing

- Power Measurement

- Power Supplies

- Process / Calibration

- Programmers / IC and RAM Testers

- Protocol Analyzers

- Prototyping

- Radiometric

- Reliability / Preventative Maint / Rotational

- RF, Microwave, EMI

- Safety Testing / Surge Testing

- Signal Generators / Counters

- Signal Level Meters - CATV / CCTV / Satellite

- Solar Analyzers

- Soldering Equipment

- BGA Rework Station

- Chemicals

- Cleaning Pins and Drills

- Depaneling Systems

- Desoldering Equipment/Rework Stations

- Desoldering Irons

- Dispensing Equipment

- Flux

- Flux Remover

- Fume Extraction

- Hot Air Guns

- Hot Air Pencils

- Lead Forming Equipment

- Nitrogen Generation

- Nozzles

- PCB Supports and Holders

- Pre-Heater

- Solder

- Solder Wick

- Soldering Equipment

- Soldering Irons

- Soldering Pots

- Soldering Robots

- Soldering Stands

- Soldering Stations

- Soldering Tip Cleaners

- Soldering Tip Thermometers

- Soldering Tweezers

- Sponges and Brass Wool

- Thermal Wire Strippers

- Tips

- Vacuum Pick-Up Tools

- Sporting / Hunting / Law Enforcement Optics

- Static Control

- Surveying / Construction Measurement

- Thermal Imagers

- Thermometers

- Thickness Gauges

- Tools

- Blackeners

- Cable Cutters

- Cable Strippers

- Cable Tie Guns

- Combination Squares

- Conduit Tools

- Crimpers

- Cutters

- Cutting Tools

- Datacom / Fiber Optic Tools

- Drill Bits and Sets

- Drill Rod

- Dry Lubricants

- Electric Screwdrivers

- Feeler Gage

- Fiber Optic Cable Tools and Fiber Scopes

- Flashlights and Headlights

- Ground Flat Stock

- Hex Drivers, Torx Drivers

- Hose Benders

- Hose Clamps

- Hot Melt

- HVAC Service Tools

- Insulated Tools

- Keystock

- Knockout Tools

- Layout Fluid

- Level Measurement

- Maintenance Kits

- Multi-Tools

- Other Hand Tools

- Pliers

- Pneumatic Hand Tool Operators

- Power Tools

- Probes & Scribes

- Punch & Die Sets

- Punchdown Tools

- Remote Hydraulic Pumps

- Screwdrivers

- Shims & Shim Stock

- Sockets & Ratchets

- Spatulas

- Telecom Service Tools

- Telescopic Tools

- Threaded Rod

- Tool Kits

- Tool Wrap

- Tweezers

- Vises

- Wire

- Wire Strippers

- Wrenches & Wrench Sets

- Toys / Cool Stuff

- Transmission Line/Station Testing

- Cable Testing

- Circuit Breaker Testers

- Corona Detection

- Dielectric Oil Testing

- High Current Detectors / Indicators

- High Voltage Detectors / Indicators

- Hot Sticks

- Phasing Sticks

- Primary Injection Test Equipment

- Safety Equipment

- Secondary Injection Test Equipment

- SF6 Gas Leak Detectors

- Transformer Testing/TTR

- Transmission Cable Height Meters

- Video Distribution Equipment

- Video Test Equipment

- Voltage / Continuity and Non-Contact Testers

- Wire Tracers / Circuit Breaker Tracers

- Workbenches

Fluke ii915/FPC3 – Acoustic Imager (2-100kHz) with LeakQ, PDQ, MecQ and Wi-Fi; Includes 3 Years of Premium Care

Brand:

23 people are viewing this product right now

$31,750.00

Shipping calculated at checkout.

Estimated delivery:5 days

FLUKE-II915/FPC3, II915 WITH 3 YEARS OF PREMIUM CARE STANDARD

- This package includes the ii915 and 3 years of Fluke Premium Care

- Enables technicians see sound as they scan hoses, fittings, and connections for leaks

- Detection range: Up to 393 feet (120 meters)

- LeakQ mode: Leak size scale, leak rate, and leak cost estimation

- PDQ mode: Partial discharge, on-device PD classification

- MecQ mode: Mechanical inspection, on-device feature to detect and document mechanical issues

- Frequency: 2 to 100 kHz

- Fast, easy, early detection of compressed gas leaks, partial discharge, and mechanical anomalies

- Uses an array of 64 micro-electronic surface-mount microphones to capture sound waves emanating from an object

- Sound signals are converted into an image and overlaid onto a visual image (SoundMap)

SKU:

Fluke II915/FPC3

EAN:

195112129272

Tags: Acoustic Imagers, Leakage Detectors

Categories: Acoustic Imagers

Have any Questions?

Feel free to Get in touch

Guarantee Safe and Secure Payment Checkout

Description

Fluke ii915/FPC3

- This package includes the ii915 and 3 years of Fluke Premium Care

- Detection range: Up to 393 feet (120 meters)

- LeakQ mode: Leak size scale, leak rate, and leak cost estimation

- PDQ mode: Partial discharge, on-device PD classification

- MecQ mode: Mechanical inspection, on-device feature to detect and document mechanical issues

Acoustic Imager (2-100kHz) with LeakQ, PDQ, MecQ and Wi-Fi; Includes 3 Years of Premium Care

Fluke acoustic imagers give you the power to see sound, transforming the way industrial inspections are carried out. Whether it’s compressed air or gas leaks, partial discharge issues, or mechanical anomalies, Fluke gives you the tools to improve the bottom line through easy and fast inspections that boost efficiency, maximize uptime, reduce costs, and improve safety. Not only do Fluke acoustic imagers detect and pinpoint the location of potential issues, but they also offer further analysis and assessment through advanced modes such as LeakQ, PDQ, and MecQ.

How do acoustic imagers work?

Fluke Acoustic Imagers are sound cameras that use an array of 64 micro-electronic surface-mount microphones to capture sound waves emanating from an object.

With advanced electronics and software algorithms, sound signals are converted into an image and overlaid onto a visual image -(SoundMap) – on the 7-inch, 1280 x 800-pixel LCD touchscreen. Acoustic imaging accurately pinpoints the direction of sound waves in a wide range of frequencies, such as those from compressed air system leaks or partial discharge. Compressor system leaks typically emit sound from 30 to 60 kHz, and partial discharges (electrical leaks) typically emit sound from 20 to 110 kHz.

Because the frequency of sound emitted from mechanical issues can exhibit many different frequencies and change with time, the ii915 includes an expanded frequency range of 2–100 kHz to give the earliest possible detection.

Reduce the frustration of unplanned downtime in four easy steps

1. Locate – Quickly and easily scan areas and pinpoint where unusual sounds are coming from – even those sounds out of range for human hearing.

2. Document – Take a screenshot of the point of interest. Then annotate and tag the photo to define follow-up action and urgency.

3. Share – Share the annotated screenshots with your team so they can respond and schedule maintenance.

4. Repair – Investigate the pinpointed areas further during planned downtime to determine what the problem is and proactively fix it.

Several versions available

Fluke offers several versions of its new ii series acoustic imager. The chart below provides a brief overview of main features for each model.

| ii500 | ii905 | ii915 | |

| LeakQ mode | Scale (1-10) | Leak size scale, rate and cost estimate | Leak size scale, rate and cost estimate |

| PDQ mode | No | No | Yes |

| MecQ mode | No | No | Yes |

| Wi-Fi | No | Yes | Yes |

| Frequency | 2 to 52 kHz | 2 to 65 kHz | 2 to 100 kHz |

| Detection range | Up to 164 feet | Up to 230 feet | Up to 393 feet |

| Visual camera resolution | 0.3 MP | 5.0 MP | 5.0 MP |

| Battery life | 6 hours | 6 hours | 6 hours |

| Memory | 20 GB | 32 GB | 32 GB |

| Tripod connector | No | Yes | Yes |

Packages with Fluke Premium Care

Fluke ii series acoustic imagers are also available as packages with 1 or 3 years of Fluke Premium Care.

When you invest in the best equipment in the industry, you want your money to go as far as possible. Fluke Premium Care provides coverage above and beyond your tool’s original product warranty, so you don’t need to worry about unexpected downtime caused by damaged test equipment, accessories, or tools in need of calibration or repair.

| Standard warranty | Premium Care | |

| Repair manufacturing defects | ✔ | ✔ |

| Accidental damage and repair | ✔ | |

| Replacement of damaged accessories | ✔ | |

| Annual calibration or performance check | ✔ | |

| Expedited calibration and repair | ✔ | |

| Priority tech support | ✔ | |

| Software updates | ✔ | |

| Expedited shipping | ✔ |

The chart below is a breakdown of acoustic imagers in this series and their corresponding care plans.

| Part number | Imager | Care plan |

| ii500 | ii500 | Standard warranty |

| ii500/FPC | ii500 | Premium Care – 1 year |

| ii500/FPC3 | ii500 | Premium Care – 3 year |

| ii905 | ii905 | Standard warranty |

| ii905/FPC | ii905 | Premium Care – 1 year |

| ii905/FPC3 | ii905 | Premium Care – 3 year |

| ii915 | ii915 | Standard warranty |

| ii915/FPC | ii915 | Premium Care – 1 year |

| ii915/FPC3 | ii915 | Premium Care – 3 year |

Leaks: Hidden Costs Due to Leaks in Compressed Air, Gas, Steam, and Vacuum Systems

While most manufacturers know these leaks exist, addressing them has been time-consuming and tedious. With the Fluke ii Series and minimal training, your maintenance technicians can begin checking for leaks during their typical maintenance routine – even during peak operation hours. The ii Series Acoustic Imagers let technicians see sound as they scan hoses, fittings, and connections for leaks. Its built-in acoustic array of tiny sensitive microphones generates a spectrum of decibel levels per frequency. Based on this output, an algorithm calculates a sound image, known as SoundMap, that is superimposed on a visual image. The SoundMap is automatically adapted depending on the frequency level selected so that background noise is filtered out, making it incredibly simple to detect compressed gas leaks.

Mechanical: First-Line Inspection to Locate Potential Mechanical Issues Early and Avoid Unplanned Downtime

Conveyor systems, with their vast size and intricate components, often pose a maintenance challenge, threatening to disrupt production and cause unplanned downtime. The Fluke ii915 with MecQ, a game-changer in the field, enables efficient scanning of large areas, detecting and documenting potential issues for more targeted maintenance. With its contactless scanning and advanced noise filtering, the Fluke ii915 Acoustic Imager with MecQ Mode ensures safety and delivers clear images even in high-noise environments. By detecting areas of concern early on, it instills confidence in its users, enabling proactive measures to prevent costly problems, surpassing traditional methods.

For professionals seeking to ensure seamless operation of large conveyance systems, the Fluke ii915 Acoustic Imager with MecQ is the ultimate choice.

Partial Discharge: The Invisible Threat…Now You Can See

Partial discharge, a serious issue that can lead to arc flash fires, blackouts, explosions, and danger to life, is now a visible threat. Whether you are inspecting insulators, transformers, switch gears, or high-voltage powerlines, the Fluke ii915 Acoustic Imager with PDQ Mode is your proactive tool. This tool, designed for high-voltage electricians, electrical test engineers, and grid maintenance teams, translates the sound of partial discharge into visuals that pinpoint the location. With an extended frequency range of 2-100 kHz, the ii915 enables early detection of potential problems, empowering you to plan maintenance and prevent catastrophic events.

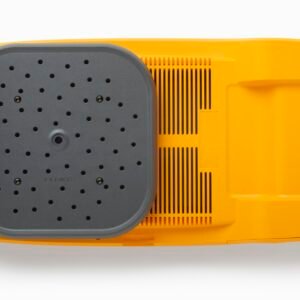

Product layout

None

Be the first to review “Fluke ii915/FPC3 – Acoustic Imager (2-100kHz) with LeakQ, PDQ, MecQ and Wi-Fi; Includes 3 Years of Premium Care”

You must be logged in to post a review.

Manuals/Guides

BrochuresManualsSpec SheetsOther

Related products

Sale

UE Systems UP100KT – Ultraprobe 100 Ultrasonic Detection Kit

Sale

Accutrak VPE Basic – Kit Ultrasonic Leak Detector

Sale

Robinair 16451 TruTrack Ultrasonic Sound Generator

Sale

Gen-Eye GR-131250 Gen-Ear Amplifier and Ground Sensor

Sale

Amprobe ULD-410 Ultrasonic Leak Detector

Our team of knowledgeable professionals is here to help you make informed decisions. Whether you need product recommendations, technical support, or guidance on your purchase, we're just a click away.

Contact Us Now:

📧 sales@nestesinstruments.com

📞 +1 (833) 763-7837

Let us assist you in finding the perfect solution!

Contact Us Now:

📧 sales@nestesinstruments.com

📞 +1 (833) 763-7837

Let us assist you in finding the perfect solution!

Reviews

There are no reviews yet.