Description

Megger BITE2 – Battery Impedance Tester, 120V, 60Hz

- Determines condition of lead-acid and NiCd cells up to 7000 Ah

- On-board Pass/Warning/Fail indications

- Robust, repeatable instruments

- On-line testing

The BITE 2 and BITE 2P Battery Impedance Test Equipment determine the condition of lead-acid and nickel-cadmium cells up to 7000 Ah. An advanced feature set has been developed that includes Pass/Warning/Fail calculations based on a user-entered baseline value, advanced printing functions and more. The case of the BITE 2P consists of both the transmitter and a carrying case for all of the standard accessories and some of the optional accessories, in an all-in-one unit. The BITE 2 and its accessories fit into a sturdy canvas case with a shoulder strap.

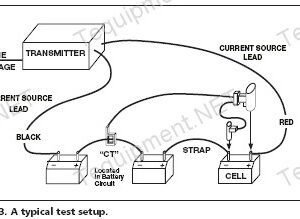

The instruments work by applying a test current across the battery string while on-line, then measuring the total current (ac ripple + test current) and the voltage drop of each cell/jar. It then calculates the impedance. They also measure dc voltage and interconnection (strap) resistance to help determine the overall condition of the entire battery string’s electrical path from terminal plate to terminal plate.

The BITE 2 and BITE 2P receiver stores the readings in its internal memory. These measurements, along with other maintenance data such as ambient and pilot cell temperatures and ac ripple current, assist in determining the overall condition of battery systems. Megger recommends that impedance measurements with the BITE 2 or BITE 2P be made part of a battery maintenance program with readings taken and recorded semiannually for flooded batteries and quarterly for VRLA.

Unlike load cycle testing that involves substantial downtime and repeated discharges, using the instruments require no battery discharge, nor do they stress the battery in any way compared to other techniques. With a test time of less than 20 seconds for each cell and intercell connector, one person can easily, quickly, and precisely measure internal cell impedance, dc terminal voltage and intercell connection resistance without taking the battery system off line.

Naturally, everything you need to perform these tests is included with the basic instruments. There is a full line of optional accessories to enhance the capabilities of the BITE 2 and BITE 2P. Both have the ability to download to a PC for data interpretation. Additionally, the BITE 2P has a built-in printer to review the active test but also to leave a hard copy record at the site.

Receiver

The battery-operated receiver incorporates the potential leads, clamp-on current sensor, and data storage capabilities. It stores more than 2000 sets of data (cell impedance, cell voltage and interconnecting strap resistance, date and time stamps) in up to 300 tests. It also allows for printing the active test for easy review and retest. Selective printing of any test and deleting oldest tests are now included features to maintain in memory the most critical tests.

At any time while performing a test, the operator can review the current test results by using arrow keys and scrolling back through the active test screen. The operator can also print the active test using the BITE 2P transmitter printer. If needed, the operator can retest any of the cells and straps in the current test. Stored data can also be downloaded via the RS-232 connector directly to a personal computer or the BITE 2P transmitter printer. One additional feature of the receiver is that if you are called away while in the middle of the test, simply shut down the instrument and it will remember where you left off in the test.

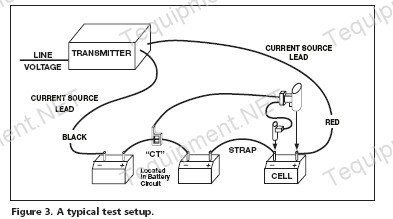

The clamp-on current sensor is connected to the receiver during testing and clamped around a convenient intertier or intercell connection within the loop created by the transmitter’s current source leads and the battery string. If the intercell or intertier connection consists of more cables than the diameter of the clamp-on current sensor can encompass, the receiver has a split-strap function.

There is an optional RopeCT TM available for large buss work. With the optional bar-code wand, additional information such as location ID, user ID, ambient and pilot cell temperatures can be recorded and stored. There is space on the printout to enter specific gravity readings.

The BITE 2 and BITE 2P work by applying a capacitively coupled ac test current across the battery string while on- line. The receiver and potential probe are placed at the cell terminals to measure the ac voltage drop and total ac current across each cell/jar. During each measurement, impedance is calculated following Ohm’s Law, displayed on the LCD and stored. The instruments also measure, display and record dc voltage and interconnection (strap) resistance to help determine the overall condition of the entire battery string’s electrical path from terminal plate to terminal plate.

The BITE 2 and BITE 2P receiver stores the readings in its internal memory. These measurements, along with other maintenance data such as ambient and pilot cell temperatures and ac ripple current, assist in determining the overall condition of battery systems. Figure 3 shows a typical test setup.

Interpretation of Readings

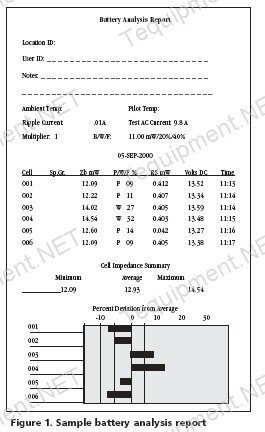

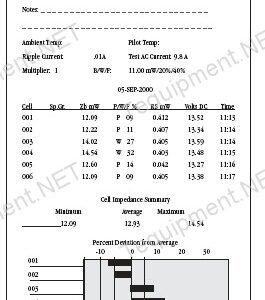

Data produced by the BITE 2 and BITE 2P can be interpreted in several modes: instantaneous, short-term and long-term time frames. An impedance distribution plot, as shown in Figure 4, assists in the analysis.

Instantaneous Interpretation

The operator can enter a baseline value from either the impedance measurements obtained at commissioning or from the Megger website. The percent changes from baseline for warning and fail levels are entered, but 20 percent and 40 percent are the default settings. The LCD on the receiver will display the status of the cell for a few seconds before proceeding to the next cell. The status of each cell/jar will be printed on the Battery Analysis Report.

Short-Term Interpretation

Impedance readings for individual cells can be used in the short term to compare with the average impedance readings for the entire battery string. Individual cell values with deviations of more than ±15 percent for flooded lead- acid, ±35 percent for VRLA, and 50 percent for NiCd cells from the battery string average typically indicate a problem with that cell. Megger recommends additional investigation of such cells including a verification of intercell connections and a single cell load-cycle test.

Long-Term Interpretation

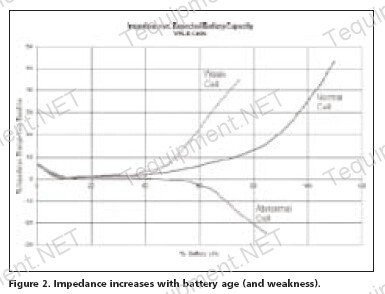

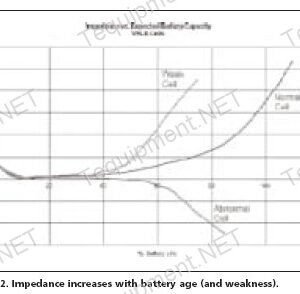

Impedance readings for the entire battery can be used in the long term to determine replacement criteria. Battery cell impedance values should be recorded and compared to previous readings to determine the position of the cell on the curve of impedance versus cell life as shown in Figure 2. Based on experience, a variation of ±20 percent from baseline for flooded lead-acid, ±40 percent for VRLA and 50 percent for NiCd cells indicate significant change in the electrical path to warrant serious evaluation of the condition of the battery system. Megger maintains a database of impedance values by some manufacturers and battery size/type. For comparison purposes, this information is available upon request.

Battery Testing/Battery Impedance Tester Template | |

|---|---|

| Max Battery Capacity | 7000 AH |

| Max Total Voltage | 275 V |

| Min Impedance | 0 m Ohms |

| Max Impedance | 100 m Ohms |

| Imp Resolution | 1 u Ohms |

| Min Operating Temp | 32 F |

| Max Operating Temp | 105 F |

| Max Test Time | 3 ns (0.000000003 s) |

| # Data Points | 2000 |

Product General Attributes | |

| Unique Features | on-line testing requiring no downtime Reqiures no battery discharge PowerDB Lite software allows data to be stored and allows custom reporting Reduced test time – less than 3 seconds per cell Measures impedance and dc voltage for all lead-acid and nickel-cadmium cells up to 7000 amp hours (Ah) |

| Warranty | 1 YEARS |

| Interfaces I/O | USB |

| Storage | Internal Memory |

| IP Rating | IP50, IP67 |

| Product Weight | 18 LBS |

| Product Height | 6.5 IN |

| Product Length | 10.6 IN |

| Product Width | 14 IN |

| Shipping Weight | 19 LBS |

| Data Logging | Yes |

| HTS/Schedule B Number | 9030330040 |

| ECCN Number | EAR99 |

| Calibration Included | |

| Battery Type | NimH |

| Power Supply Voltage | 120V/220V Universal, Battery Powered |

| Country of Origin | United States |

| Shipping Height | 7 IN |

| Shipping Length | 11.5 IN |

| Shipping Width | 19.5 IN |

Reviews

There are no reviews yet.