No products in the cart.

Need help? Call us:

+1 (833) 763-7837

Menu

Categories

- Accessories

- Air Purification Accessories

- Antennas

- Attenuators

- Barcode Scanners

- Batteries and Chargers

- Bottles and Dispensers

- Cables - Misc

- Carrying Straps, Lanyards and Harnesses

- Carts

- Case and Cart Accessories

- Cases

- Cathodic Protection Accessories

- Coaxial

- Crimper Accessories

- Datacom Accessories

- Dry Block Bath Inserts

- EMI Accessories

- Enclosure Accessories

- FIber Optic Accessories

- Fiber Optic Cables

- Gas Detection Accessories

- General Accessories

- GPIB Adapters

- Heating Elements

- Hipot Accessories

- Hoses - Miscellaneous

- HVAC Accessories

- Induction Heater Accessories

- Input Cards

- Jacks /Adapters /Plugs /Clips /Terminators/Coaxial

- Jobsite Storage and Cabinets

- Knockout Accessories

- Lab Accessories

- LCR Test Fixtures

- LED and LCD Displays

- Manuals

- Material Handling Accessories

- Microphones

- Microscope Accessories

- Motors

- Options

- Pinhole/Holiday Detector Accessories

- Plumbing Accessories

- Precision Measuring Instrument Accessories

- Pressure Calibrator Modules

- Printers and Printing Supplies

- Probes

- Rack Mounts and Stands

- Repair Parts and Fuses

- Scale Accessories

- Shunts

- Software

- Soldering Accessories

- Spectrum Analyzer Accessories

- Static Control Accessories

- Switch and Semiconductor Modules/Access

- Test Fixtures

- Test Leads and Instrument Accessory Kits

- Thermal Imager Accessories

- Training and Education

- Underground Utility Location Accessories

- Vibration Accessories

- Video Accessories

- Voltage Transformer

- Warranty and Calibration

- Amplifiers / Preamps / Preamplifiers

- Audio Equipment

- Automotive Test Tools

- Battery Testing

- Blower Door and Duct Testing

- Borescopes / Boroscopes

- Clamp Meters

- Cleanroom

- Color and Appearance

- Conduit Benders

- Current Sensors

- Datacom and Networking Products

- Dataloggers Data Acquisition

- Decade Boxes

- Distance Meter

- Electrical Parts and Products

- Cable and Wire

- Cable Reels

- Electrical Cord

- Electrical Jumpers and Pigtails

- Electrical Parts

- Electrical Plugs and Connectors

- Line Splitters

- Lockout / Tagout

- Outlet Boxes

- Pulling Products

- Pushbutton Pendant Stations

- Receptacle Testers

- Temporary Power Distribution

- Terminal Blocks and Strips

- Terminals and Crimps

- Wall Plates

- Wire Management

- Wire Ties

- Work Lighting and String Lighting

- Enclosures and Boxes

- Environmental Testers / Physical Property

- Anemometer / Air Flow

- Barometers and Altimeters

- Chlorine Tester

- Dissolved Oxygen Meter / Fluoride

- EMF / ELF Meter

- Heat Index Monitors

- Humidity Meters

- Hygrometers

- Moisture Meters

- Nuclear Radiation Monitors

- PH / ORP Meters

- Psychrometer

- Refractometers / BRIX

- Scales / Weight

- Sound Level Meters

- Stopwatches / Timers / Clocks

- Water Quality Accessories

- Water Quality Meters

- Weather Measurement

- Wind Tunnels

- Flow Measurement

- Force / Torque / Hardness Meters

- Gas Detection

- Ground Testers

- Health and Safety

- HVAC Equipment and Instruments

- Automotive RRR Machines

- Brazing

- Combustion Analyzers

- Hose Adapters, Valves and Parts

- HVAC - Testing - Adjusting - Balancing

- HVAC Equipment - Misc

- HVAC Manifolds and Gauges

- HVAC Vacuum Pumps

- Refrigerant Leak Detectors

- Refrigerant Recovery Machines

- Refrigerant Recovery Tanks

- Smoke Pump Test Kits

- Tubing Tools

- Vacuum Gauges

- Hydraulic Cylinders

- Indoor Air Quality

- LCR Meters / Impedance Measurement Products

- Leakage Detectors

- Life Sciences Equipment

- Autoclaves and Sterilization

- Bunsen Burners

- Centrifuges

- Cold Storage

- Colony Counters

- Dry Block Heaters and Cooling Blocks

- Environmental Test Chambers

- Flame Photometers

- Flocculators

- Fluidized Bed Baths

- Gel Imaging Electrophoresis

- Glassware Washers-Dryers

- Heating Mantles / Electromantles

- Homogenizers

- Incubators

- Kjeldahl Apparatus

- Lab Apparatus - Misc

- Laboratory Ovens

- Laboratory Pumps

- Laboratory Water Purification Systems

- Magnetic Bead Based Purification

- Melting Point Apparatus

- Mixers Rotators and Stirrers

- Pipettes

- Reaction Station

- Recirculating Chillers / Coolers

- Refrigerated Heating Circulators

- Rotary Evaporators

- Shakers and Rockers

- Slide Warmers

- Spectrophotometer

- Thermal Cycler / PCR

- Titrators

- Water Baths and Liquid Baths

- Logic Analyzers

- Materials Testing

- Megohmmeter / Insulation Resistance Testers

- Micro-Ohmmeter / Milliohmmeter

- Microscopes

- Multimeters

- Network Analyzer

- Oscilloscopes

- Panel Meters

- Personal Protective Equipment

- Phase / Motor / Transformer Testing

- Power Measurement

- Power Supplies

- Process / Calibration

- Programmers / IC and RAM Testers

- Protocol Analyzers

- Prototyping

- Radiometric

- Reliability / Preventative Maint / Rotational

- RF, Microwave, EMI

- Safety Testing / Surge Testing

- Signal Generators / Counters

- Signal Level Meters - CATV / CCTV / Satellite

- Solar Analyzers

- Soldering Equipment

- BGA Rework Station

- Chemicals

- Cleaning Pins and Drills

- Depaneling Systems

- Desoldering Equipment/Rework Stations

- Desoldering Irons

- Dispensing Equipment

- Flux

- Flux Remover

- Fume Extraction

- Hot Air Guns

- Hot Air Pencils

- Lead Forming Equipment

- Nitrogen Generation

- Nozzles

- PCB Supports and Holders

- Pre-Heater

- Solder

- Solder Wick

- Soldering Equipment

- Soldering Irons

- Soldering Pots

- Soldering Robots

- Soldering Stands

- Soldering Stations

- Soldering Tip Cleaners

- Soldering Tip Thermometers

- Soldering Tweezers

- Sponges and Brass Wool

- Thermal Wire Strippers

- Tips

- Vacuum Pick-Up Tools

- Sporting / Hunting / Law Enforcement Optics

- Static Control

- Surveying / Construction Measurement

- Thermal Imagers

- Thermometers

- Thickness Gauges

- Tools

- Blackeners

- Cable Cutters

- Cable Strippers

- Cable Tie Guns

- Combination Squares

- Conduit Tools

- Crimpers

- Cutters

- Cutting Tools

- Datacom / Fiber Optic Tools

- Drill Bits and Sets

- Drill Rod

- Dry Lubricants

- Electric Screwdrivers

- Feeler Gage

- Fiber Optic Cable Tools and Fiber Scopes

- Flashlights and Headlights

- Ground Flat Stock

- Hex Drivers, Torx Drivers

- Hose Benders

- Hose Clamps

- Hot Melt

- HVAC Service Tools

- Insulated Tools

- Keystock

- Knockout Tools

- Layout Fluid

- Level Measurement

- Maintenance Kits

- Multi-Tools

- Other Hand Tools

- Pliers

- Pneumatic Hand Tool Operators

- Power Tools

- Probes & Scribes

- Punch & Die Sets

- Punchdown Tools

- Remote Hydraulic Pumps

- Screwdrivers

- Shims & Shim Stock

- Sockets & Ratchets

- Spatulas

- Telecom Service Tools

- Telescopic Tools

- Threaded Rod

- Tool Kits

- Tool Wrap

- Tweezers

- Vises

- Wire

- Wire Strippers

- Wrenches & Wrench Sets

- Toys / Cool Stuff

- Transmission Line/Station Testing

- Cable Testing

- Circuit Breaker Testers

- Corona Detection

- Dielectric Oil Testing

- High Current Detectors / Indicators

- High Voltage Detectors / Indicators

- Hot Sticks

- Phasing Sticks

- Primary Injection Test Equipment

- Safety Equipment

- Secondary Injection Test Equipment

- SF6 Gas Leak Detectors

- Transformer Testing/TTR

- Transmission Cable Height Meters

- Video Distribution Equipment

- Video Test Equipment

- Voltage / Continuity and Non-Contact Testers

- Wire Tracers / Circuit Breaker Tracers

- Workbenches

Megger BITE2P – Battery Impedance Tester with Built-in Printer

Brand:

21 people are viewing this product right now

$12,485.00

Shipping calculated at checkout.

Estimated delivery:5 days

Battery Impedance Tester with Built-in Printer, 120V, 60Hz

- BITE2P Battery Impedance Tester with Built-in Printer

- On-line testing requiring no downtime.

- Enhanced printing and memory functions.

- Calculates impedance automatically and stores results for on-site review.

- Requires no battery discharge.

- Receiver has an RS-232 connector for downloading stored data to a personal computer.

- Reduced test time: less than 30 seconds for each cell.

- Measures impedance and dc voltage values for all lead acid and nickel-cadmium cells up to 7000 Ah.

- Stores more than 2000 sets of readings in up to 300 tests.

SKU:

Megger BITE2P

Tags: Battery Impedance Tester, Battery Testing

Categories: Battery Impedance Tester

Have any Questions?

Feel free to Get in touch

Guarantee Safe and Secure Payment Checkout

Description

Megger BITE2P – Battery Impedance Tester with Built-in Printer

- Receiver has an RS-232 connector for downloading stored data to a personal computer.

- Reduced test time: less than 30 seconds for each cell.

- Measures impedance and dc voltage values for all lead acid and nickel-cadmium cells up to 7000 Ah.

- Stores more than 2000 sets of readings in up to 300 tests.

The BITE2P Battery Impedance Test Equipment determine the condition of lead-acid and nickel-cadmium cells up to 7000 Ah. An advanced feature set has been developed that includes Pass/Warning/Fail calculations based on a user-entered baseline value, advanced printing functions and more. The case of the BITE2P consists of both the transmitter and a carrying case for all of the standard accessories and some of the optional accessories, in an all-in-one unit.

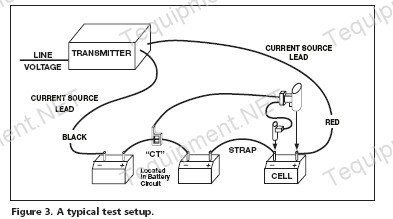

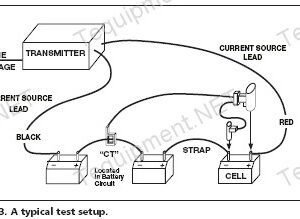

The instruments work by applying a test signal across the battery string while on-line, then calculates impedance based on simultaneous measurements of current and resulting voltage drop of each cell/jar. They also measure dc voltage and interconnection (strap) resistance to help determine the overall condition of the entire battery string’s electrical path from terminal plate to terminal plate.

In addition, the BITE2P measure ac ripple current which, if too high and over an extended period of time, can damage the battery by heating it. (An increase of battery temperature by 18ºF/10ºC will halve the life of lead-acid batteries.) Battery manufacturers generally recommend a limit of 5A of ac ripple current for every 100 Ah of battery capacity. The first measurement that the instruments take is ac ripple current which should be trended.

The BITE2P receiver stores the readings in its internal memory. These measurements, along with other maintenance data such as ambient and pilot cell temperatures and ac ripple current, assist in determining the overall condition of battery systems. Megger recommends that impedance measurements with the BITE2P be made part of a battery maintenance program with readings taken and recorded semiannually for flooded batteries and quarterly for VRLA.

Unlike load cycle testing that involves substantial downtime and repeated discharges, using the instruments require no battery discharge, nor do they stress the battery in any way compared to other techniques. With a test time of less than 15 seconds for each cell and intercell connector, one person can easily, quickly, and precisely measure internal cell impedance, dc terminal voltage and intercell connection resistance without taking the battery system off line and evaluate charger condition also.

Naturally, everything you need to perform these tests is included with the basic instruments. There is a full line of optional accessories to enhance the capabilities of the BITE2P. BITE2P have the ability to download to a PC for data interpretation and to PowerDB, Megger’s battery database management software. Additionally, the BITE2P has a built-in printer to review the active test and also to leave a hard copy record at the site.

Features and Benefits

- On-line testing requiring no downtime.

- Enhanced printing and memory functions.

- Calculates impedance automatically and stores results for on-site review.

- Requires no battery discharge.

The BITE2P provides an alternative to the substantial downtime and repeated discharges required when performing load cycle testing by allowing users to perform on-line testing with no downtime. Compared with other methods, this test method does not stress the batteries under test. Test times are less than 15 seconds for each cell and intercell connector. This means one person could easily perform all battery tests with the BITE2P.

The BITE2P unit includes everything needed to perform battery tests including the transmitter, receiver, 20ft fused current source leads, current sensor, CT extension cable, and a built-in printer. The BITE2P also comes with the free version of Megger’s battery management database software called PowerDB LITE. This free version provides all necessary functions however it does not allow for custom reports. The full version, PowerDB, supports this feature.

The receiver portion of the BITE2P includes potential leads, a clamp-on current sensor, and data storage capabilities for up to 2000 data sets from 300 tests. Any of these stored tests as well as the active test can be printed directly from the BITE2P transmitter. Active test results can be viewed at any time during the test. Data can also be downloaded to a PC via a built-in RS-232 connection. The receiver also includes a split-strap function in the event that an intercell connection includes more cables than the clamp-on current sensor can hold.

The BITE2P transmitter provides the capacitively coupled AC test signal. This helps avoid transients on the DC buss. Test current is applied to cells from the transmitter via source leads. The BITE2P transmitter also includes an LCD screen and built-in charger for the receiver, as well as the built-in printer.

Application

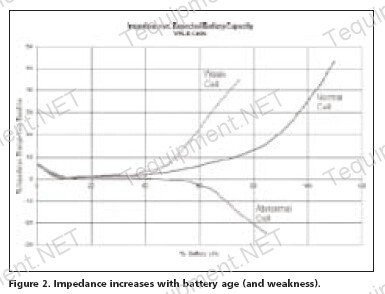

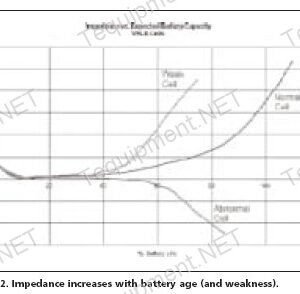

Generally, a battery’s internal impedance increases as its capacity decreases. This is due to a combination of age, ambient temperature, discharge history, and other factors. When measuring impedance with the BITE2P, users might discover problems with the batteries under test which could result from plate sulphation, post-seal corrosion, dry-out, and poor intracell and intercell connections. With this information, operators can specify maintenance procedures including:

- Cell replacement criteria based on impedance trends.

- Jumpering out a cell or two.

- Clean and/or retorque intercell connectors.

- Shorten the maintenance interval, etc.

Typical installations that can be tested using the BITE2and BITE2P include:

- Electrical power generation plants.

- Substations: utility, railroad, industrial

- Telecommunications facilities: CO, Wireline, Wireless, MTSO

- UPS systems

- Railroad: Signals and Communications, substation

- Aircraft power supplies

- Marine, military

Test Procedure

The BITE2P work by applying a capacitively coupled ac test signal across the battery string while on-line. The receiver and potential probe are placed at the cell terminals to measure the signal and resulting voltage drop for each cell/jar. During each measurement, impedance is calculated following Ohm’s Law, displayed on the LCD and stored. The instruments also measure, display and record dc voltage and interconnection (strap) resistance to help determine the overall condition of the entire battery string’s electrical path from terminal plate to terminal plate. It also measure ac ripple current, a charger parameter.

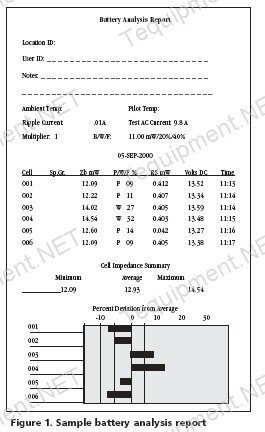

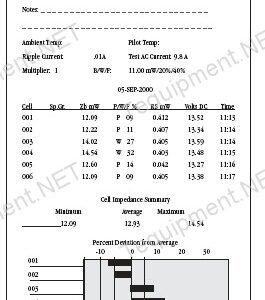

The BITE2P receiver stores the readings in its internal memory. These measurements, along with other maintenance data such as ambient and pilot cell temperatures and ac ripple current, assist in determining the overall condition of battery systems. Figure 2 shows a typical test setup.

Interpretation of Test Readings

The BITE2P allows users to interpret data in three modes: instantaneous, short-term, and long-term.

In instantaneous mode, the user must enter a baseline value which test result will be compared against. The percent change thresholds from baseline for warning and fail levels must also be pre-set by the user, otherwise the default values are 20% for warning and 40% for fail. The BITE2P will calculate these values for each cell and display cell status on-screen.

In short-term interpretation, impedance values for individual cells are compared with the average impedance reading across the entire battery string. Individual cell values with deviations from the battery string average of more than ±15% for flooded lead-acid, ±35% for VRLA, and 50% for NiCd cells typically indicate a problem with that cell.

Impedance values can be used in long-term interpretation to determine if batteries should be replaced. Impedance values must be compared with readings from previous tests to determine the position of a battery on the impedance versus cell life curve. Typically, a variation of ±20% from baseline for flooded lead-acid, ±40% for VRLA, and 50% for NiCd cells signals that the condition of the battery system must be evaluated.

Battery Testing/Battery Impedance Tester Template | |

|---|---|

| Max Battery Capacity | 7000 AH |

| Max Total Voltage | 275 V |

| Min Impedance | 0 m Ohms |

| Max Impedance | 100 m Ohms |

| Imp Resolution | 1 u Ohms |

| Min Operating Temp | 32 F |

| Max Operating Temp | 105 F |

| Max Test Time | 3 ns (0.000000003 s) |

| # Data Points | 2000 |

Product General Attributes | |

| Unique Features | on-line testing requiring no downtime Reqiures no battery discharge PowerDB Lite software allows data to be stored and allows custom reporting Reduced test time – less than 3 seconds per cell Measures impedance and dc voltage for all lead-acid and nickel-cadmium cells up to 7000 amp hours (Ah) |

| Warranty | 1 YEARS |

| Interfaces I/O | USB |

| Storage | Internal Memory |

| IP Rating | IP30, IP67 |

| Product Weight | 29 LBS |

| Product Height | 7.5 IN |

| Product Length | 14.6 IN |

| Product Width | 18.5 IN |

| Shipping Weight | 30 LBS |

| Data Logging | Yes |

| HTS/Schedule B Number | 9030330040 |

| ECCN Number | EAR99 |

| Calibration Included | |

| Battery Type | NimH |

| Power Supply Voltage | 120V/220V Universal, Battery Powered |

| Country of Origin | United States |

| Shipping Height | 7 IN |

| Shipping Length | 11.5 IN |

| Shipping Width | 19.5 IN |

Be the first to review “Megger BITE2P – Battery Impedance Tester with Built-in Printer”

You must be logged in to post a review.

Manuals/Guides

BrochuresManuals

- Megger Battery Testing Guide

- Megger Bite2 and Bite2P Instruction Manual

- Megger Power DB for BITE Products

- Megger Quick Reference Guide for BITE2P

- Megger Application Note - Battery Ohmic Data Analysis

- Megger Bite Series Measuring Jars with Multiple Cells using Power DB Application Note

- Megger Bite Series NERC testing Application Note

- Megger Bite Series Setting Chart Limits Power DB Application Note

- Megger Bite2 and Bite2P Field Calibration Verification Application Note

| Weight | 30 lbs |

|---|---|

| Dimensions | 14.6 × 18.5 × 7.5 in |

Related products

Sale

Eagle Eye LB-1000 – Battery Charger / Discharger / Activator

Sale

Eagle Eye LB-12/24-600-CCD – 12V/24V, 600A Constant Current Load Bank with Data and Software

Sale

Eagle Eye LB-125-200-CC – 125V, 200A Constant Current Load Bank

Sale

Eagle Eye LB-380-100-CCD – DC Load Bank with Data and Software

Our team of knowledgeable professionals is here to help you make informed decisions. Whether you need product recommendations, technical support, or guidance on your purchase, we're just a click away.

Contact Us Now:

📧 sales@nestesinstruments.com

📞 +1 (833) 763-7837

Let us assist you in finding the perfect solution!

Contact Us Now:

📧 sales@nestesinstruments.com

📞 +1 (833) 763-7837

Let us assist you in finding the perfect solution!

Reviews

There are no reviews yet.